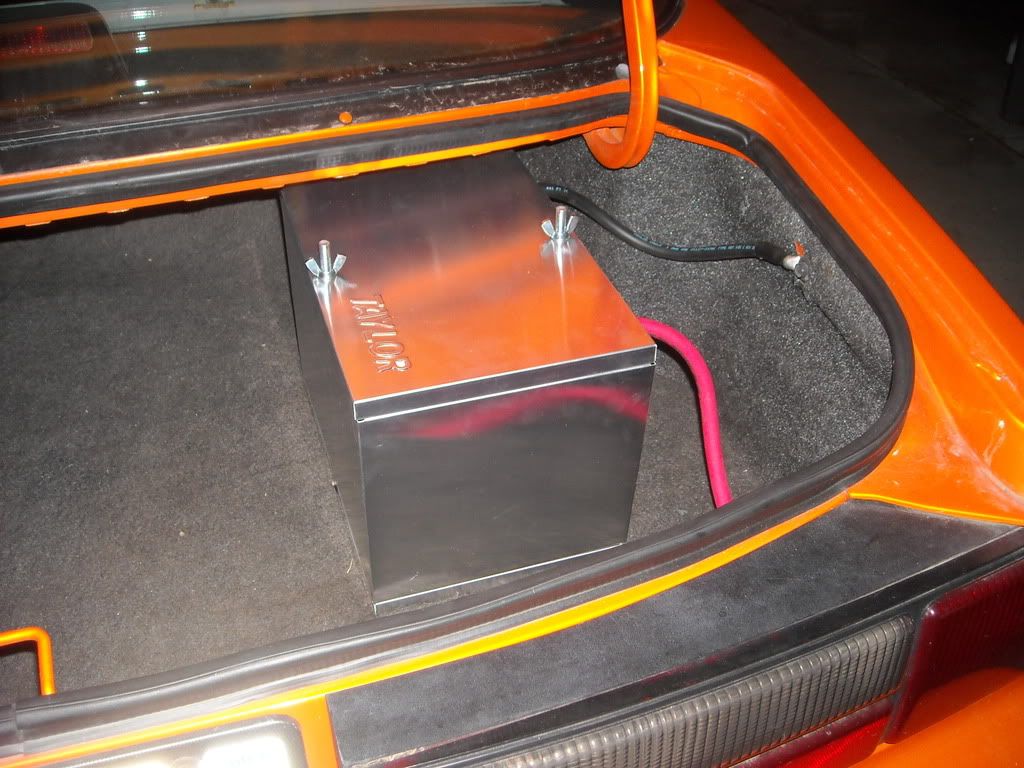

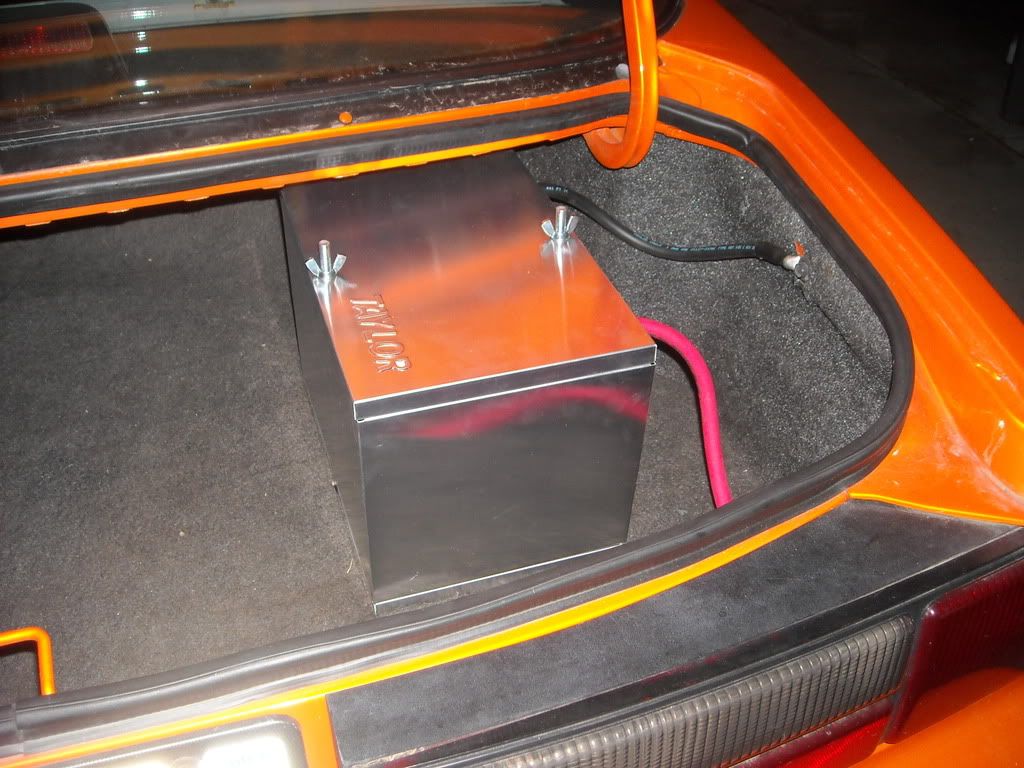

1st, Let me start by saying that this install is not as easy as it seems. It is a little time consuming. 2nd The Taylor Battery relocation kit that I purchased is really nice, but it does not come with enough positive cable to do the job and now I have to get some more in order to complete the job.

I started by figuring out that if you want to locate the battery over the right rear tire you will have to drop the fuel tank, otherwise you will drill 2 holes in it!! Also you can't fit your hand up in there to put the nuts on the all thread that holds the box down.

After dropping the tank and getting the box bolted in I went to install my cutoff switch. While trying to mount it I noticed that the rear bumper was in my way, so what the hell?! I removed it! I cut it off with a sawzall. That sucker was 37lbs! After that was out of the way I found the center of the bumper cover in front of the license plate and drilled my mounting hole.

Once the switch was mounted I started to run the wires. Here is a wiring diagram in case any of you are looking to do this in the near future.

First wire I ran was the pos. from the battery to one side of the batt cut-off switch. I ran it through a hole in the bottom of the trunk.

Next I realized that I would not have enough cable to reach the engine compartment where the solenoid is located, so I moved on to finding a good ground for the batt. I found a spot in the trunk and ground all the paint off and drilled a hole to mount the negative terminal. After mounting the Neg. I pulled out my multi-meter to insure that I indeed have a good ground.

Next I wanted to use a bulkhead connector that I purchased through Summit. I am using it partially because I do not have room on the solenoid for all of these cables. Also I will now mount my alternator wiring to the bulkhead connector and get rid of some wiring and make more room on the solenoid as well. After locating an existing hole in the firewall I decided to run it through the wiper arm tunnel under the plastic cowling vent. There is a screen on the passenger side that runs into the car, which is where I will run my cable to the other side of the cut-off switch.

Then I made the wire that goes from the solenoid to the bulkhead connector. Tomorrow I am going to Harbor freight to buy a heat gun, so I can heat shrink all of my wiring terminals.

Well guys I am slowly knocking out the stuff that I have to get down before the big race! I still have to finish this job, install the spool with 31 spline axles and c-clip eliminators, change rear springs, install anti-roll bar, paint weld and re-install roll-bar, put interior back together, install engine with newly stalled tq converter and hook up all wiring and exhaust!!! Sigh...............Well, Thanks for looking.

Taylor Box mounted

Cut-off switch mounted

Bulhead connector mounted

Back side of connector

current state of car

Current state of car

I started by figuring out that if you want to locate the battery over the right rear tire you will have to drop the fuel tank, otherwise you will drill 2 holes in it!! Also you can't fit your hand up in there to put the nuts on the all thread that holds the box down.

After dropping the tank and getting the box bolted in I went to install my cutoff switch. While trying to mount it I noticed that the rear bumper was in my way, so what the hell?! I removed it! I cut it off with a sawzall. That sucker was 37lbs! After that was out of the way I found the center of the bumper cover in front of the license plate and drilled my mounting hole.

Once the switch was mounted I started to run the wires. Here is a wiring diagram in case any of you are looking to do this in the near future.

First wire I ran was the pos. from the battery to one side of the batt cut-off switch. I ran it through a hole in the bottom of the trunk.

Next I realized that I would not have enough cable to reach the engine compartment where the solenoid is located, so I moved on to finding a good ground for the batt. I found a spot in the trunk and ground all the paint off and drilled a hole to mount the negative terminal. After mounting the Neg. I pulled out my multi-meter to insure that I indeed have a good ground.

Next I wanted to use a bulkhead connector that I purchased through Summit. I am using it partially because I do not have room on the solenoid for all of these cables. Also I will now mount my alternator wiring to the bulkhead connector and get rid of some wiring and make more room on the solenoid as well. After locating an existing hole in the firewall I decided to run it through the wiper arm tunnel under the plastic cowling vent. There is a screen on the passenger side that runs into the car, which is where I will run my cable to the other side of the cut-off switch.

Then I made the wire that goes from the solenoid to the bulkhead connector. Tomorrow I am going to Harbor freight to buy a heat gun, so I can heat shrink all of my wiring terminals.

Well guys I am slowly knocking out the stuff that I have to get down before the big race! I still have to finish this job, install the spool with 31 spline axles and c-clip eliminators, change rear springs, install anti-roll bar, paint weld and re-install roll-bar, put interior back together, install engine with newly stalled tq converter and hook up all wiring and exhaust!!! Sigh...............Well, Thanks for looking.

Taylor Box mounted

Cut-off switch mounted

Bulhead connector mounted

Back side of connector

current state of car

Current state of car