When you are broke it changes things though lol. His oil pan was annihilated when his engine exploded.

Honestly I told him I wasn't sure if it was salvageable, but I would give it a shot. If I couldn't fix it I wouldn't charge him.

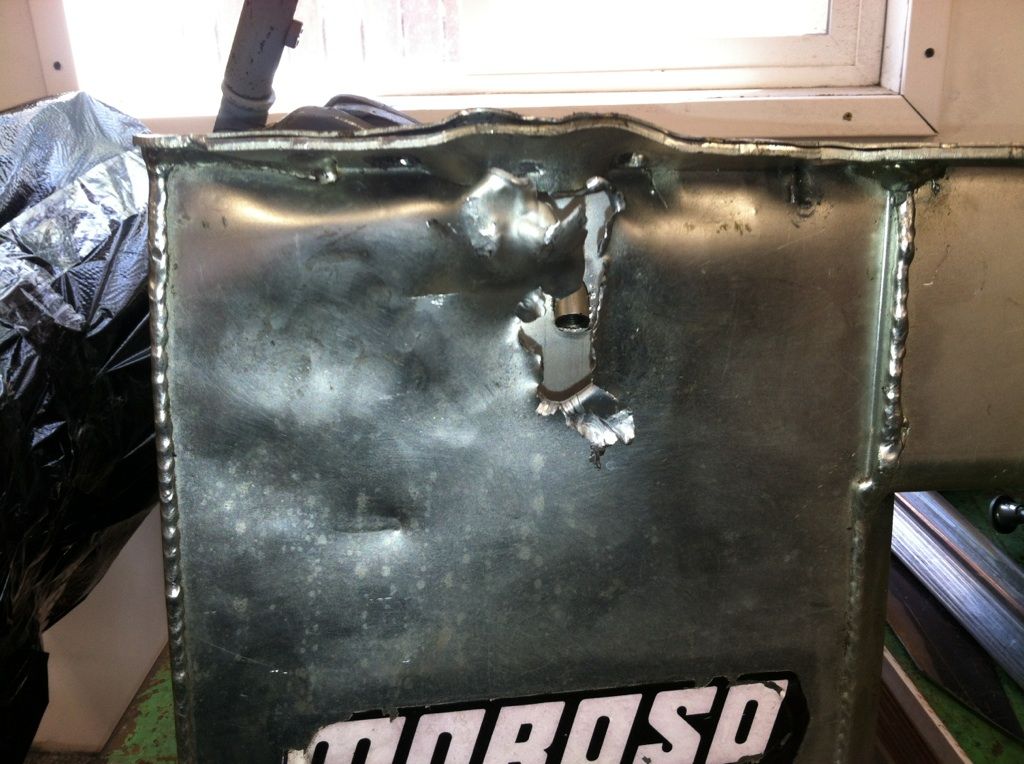

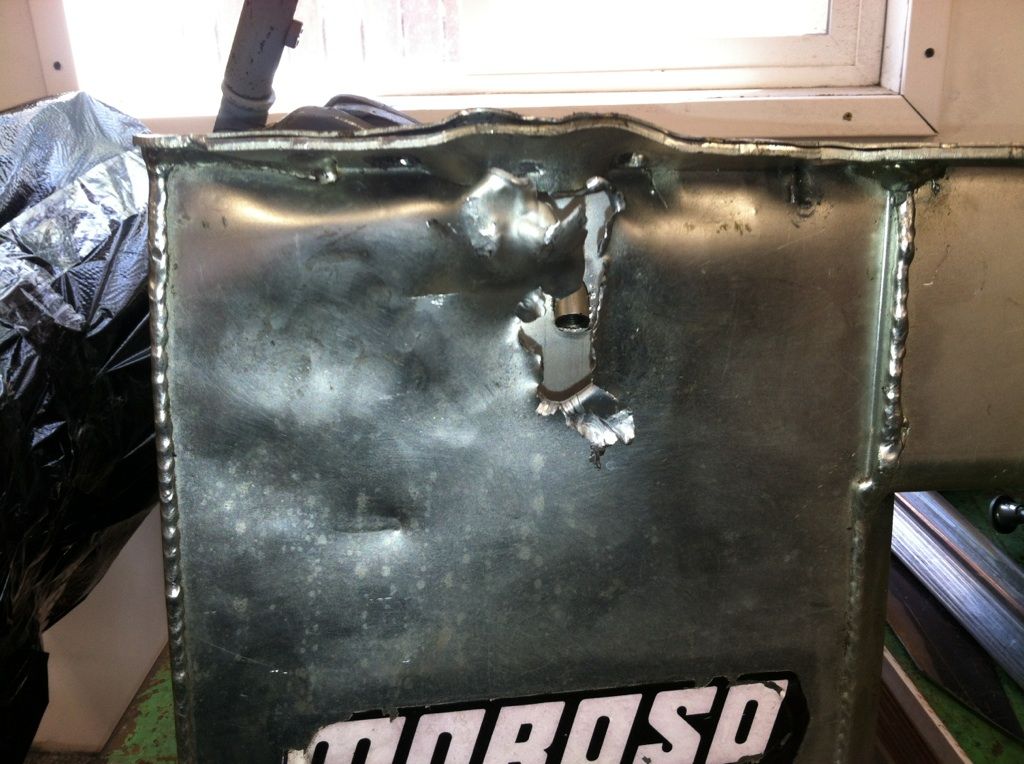

Here is what I had to work with.

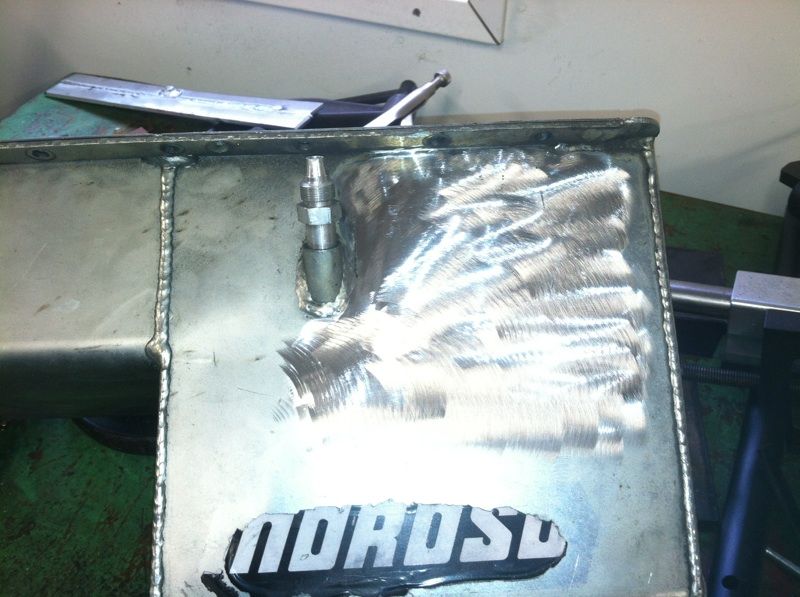

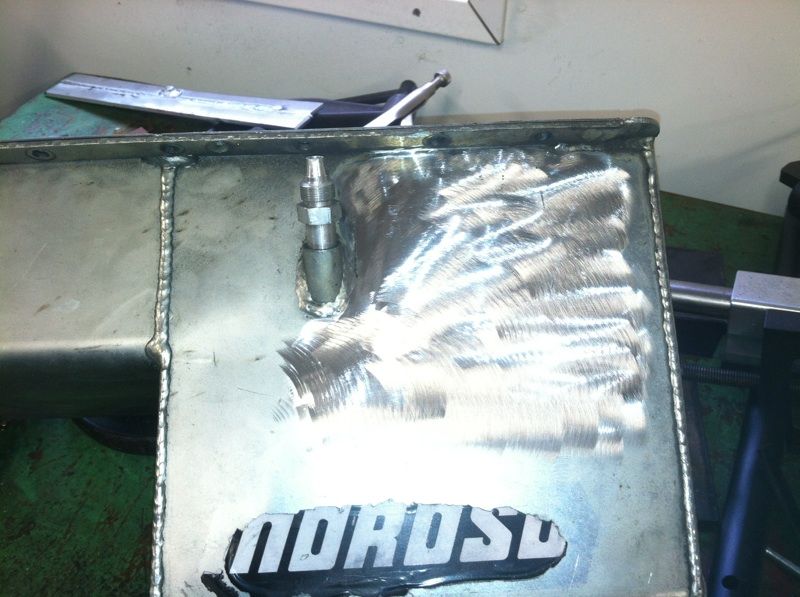

After getting a plan together I made the patches and pieces of the oil pan rail. I didn't really take pics of the rail pieces, but you will notice in the pics if you look closely how the rail starts coming together.

I wanted to start on the hard part which was the side where the rail was destroyed. Lucky for me I had a 351w block in the garage that I could bolt the pan to for mock up and welding.

I tried to straighten the pan as much as I could before cutting it.

You can see in this picture how the extra material on the oil pan rail was trimmed and dressed up.

Now that the hard side was complete I went over to the easy side. I'm going to fill it with water tomorrow to make sure it isn't leaking. If there are any pin holes I will weld them up.

Honestly I told him I wasn't sure if it was salvageable, but I would give it a shot. If I couldn't fix it I wouldn't charge him.

Here is what I had to work with.

After getting a plan together I made the patches and pieces of the oil pan rail. I didn't really take pics of the rail pieces, but you will notice in the pics if you look closely how the rail starts coming together.

I wanted to start on the hard part which was the side where the rail was destroyed. Lucky for me I had a 351w block in the garage that I could bolt the pan to for mock up and welding.

I tried to straighten the pan as much as I could before cutting it.

You can see in this picture how the extra material on the oil pan rail was trimmed and dressed up.

Now that the hard side was complete I went over to the easy side. I'm going to fill it with water tomorrow to make sure it isn't leaking. If there are any pin holes I will weld them up.