Bobby, not being a smartass as this is an actual question.....

How are yo going to dial in the valvetrain? I have read about it and stuff, but have never had to mess with it so I dont know how to. Just wondering what way you do it. Thanks.

Gib

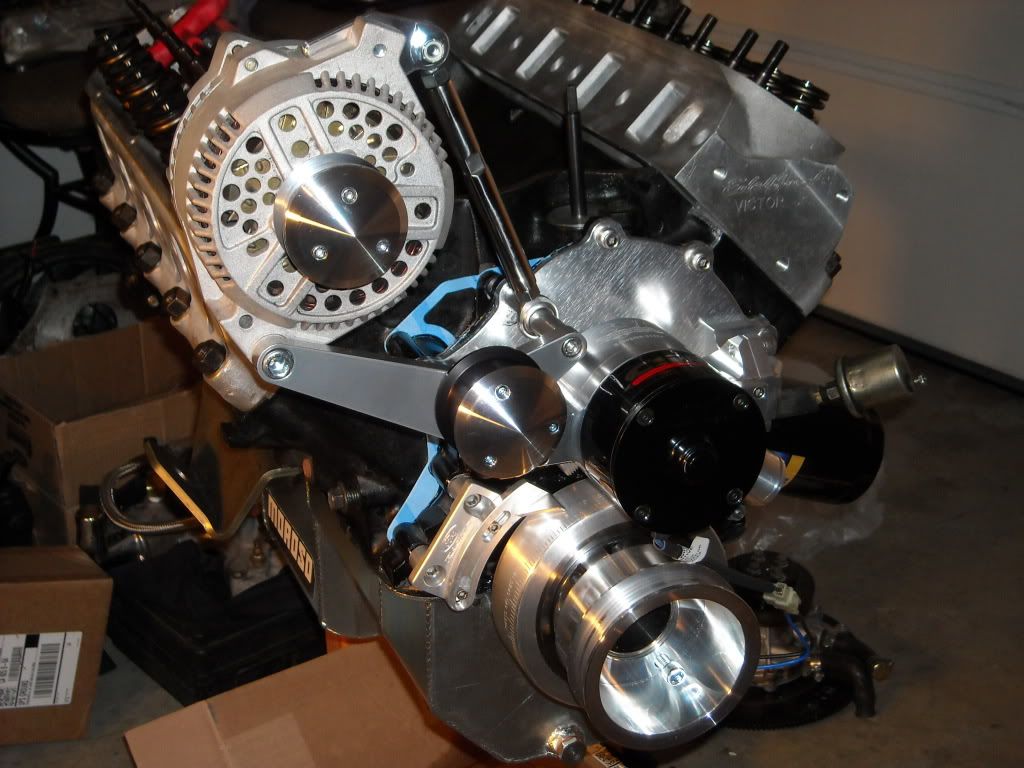

Well pushrod length is the hard part, but I'm not sure if that's what you are asking? I think that you are talking about the roller rockers.

Well hydraulic rollers will be set up a little different than a mechanical roller (solid), but this is the way to do it.

First you have to know what your valve lash should be (this only applies to solid) in my case it's Hot lash .020". Since the engine will be started cold you actually subtract .006" from that number for initial set up for aluminum heads and -.004" for iron heads.

Mine are aluminum so I will start at .014". You will need a feeler gauge of course.

Well start with the number one cylinder. Manually rotate the crankshaft and watch the exhaust valve/lifter on the number 1 cylinder. As soon as it starts to open, STOP! The intake lifter is now and the base circle of the cam and ready to be adjusted. Now with the feeler gauge in place start turning down the rocker adjusting nut until you feel a slight drag and then lock down the polylock.

Now move on to the exhaust side. Rotate the crank in its normal rotation (clockwise) watching the same intake valve that you just finished adjusting. It will go to full open and then begin to close. When it is almost closed, STOP! You are now ready to adjust the exhaust valve.

Repeat this for the rest of the cylinders.

For a hydraulic set up you would tighten the adjusting nut until you hit zero lash and turn the adjusting nut 1/2 turn more and lock it down.

I'm happy to answer any questions that you might have. If anything doesn't make sense let me know.