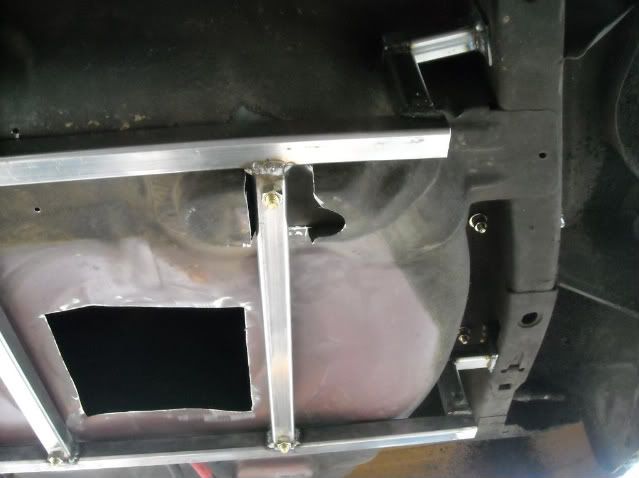

I began my fuel cell install today. With my stock tank out of the way I was ready to drill some holes today. I started by making a template of the cell and marked the square that will need to be cut out for the sump.

On my way home from work I stopped by California Metals and picked up a 20ft stick of 1" square tubing so I can build support beams under the car to bolt the cell to since the trunk is so flimsy.

Next, since all of the fuel cells that I shopped had -8AN fittings built in I'm modifying the brand new tank to my liking. The A1000 fuel system recommends a minimum of 1/2" (-8AN) hose for the feed, but also state that the pump will be more efficient with a larger hose. Also since the system will be Y'ed off I didn't want the same size line splitting in 2 different directions. It would be better to have a larger line split off than the same size line split off. Are we tracking???

With that said I cut off the -8AN fitting and with a sanding disc took it down to the base and enlarged the hole. Tomorrow at work I will have a -10AN fitting welded in it's place.

On my way home from work I stopped by California Metals and picked up a 20ft stick of 1" square tubing so I can build support beams under the car to bolt the cell to since the trunk is so flimsy.

Next, since all of the fuel cells that I shopped had -8AN fittings built in I'm modifying the brand new tank to my liking. The A1000 fuel system recommends a minimum of 1/2" (-8AN) hose for the feed, but also state that the pump will be more efficient with a larger hose. Also since the system will be Y'ed off I didn't want the same size line splitting in 2 different directions. It would be better to have a larger line split off than the same size line split off. Are we tracking???

With that said I cut off the -8AN fitting and with a sanding disc took it down to the base and enlarged the hole. Tomorrow at work I will have a -10AN fitting welded in it's place.